VFSTR University

the flagship institution of Vignan’s Group of Educational Institutions, is NAAC ‘A’ accredited institution, ranked 88 by National Institutional Ranking Framework of MHRD, Government of India started several Centres of Excellence, research centres, Innovation centres, motivational classes, business communication skills, product development orientation and entrepreneurship cell supplemented with human values are the process principles adopted in the university to mold students for their self-awareness and to build competence.

CoExAMMPC

though started to function from July 2016 it was officially inaugurated by Shri MuppavarapuVenkaiah Naidu, Hon’ble Minister of Housing and Urban Poverty Alleviation and Information and Broadcasting on 27th Sept. 2017. The CoExAMMPC is devoted to the design, synthesise, and fundamental understanding of materials that are capable of enhancing the advancement of science and technology, industrial production, economic growth and improving the quality of life for the mankind.

CoExAMMPC is a material research and technology centre instituted by the university in the year 2015 for promoting cutting-edge research in the areas of advanced materials.

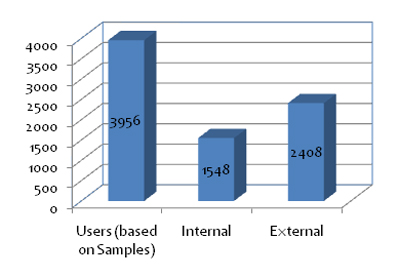

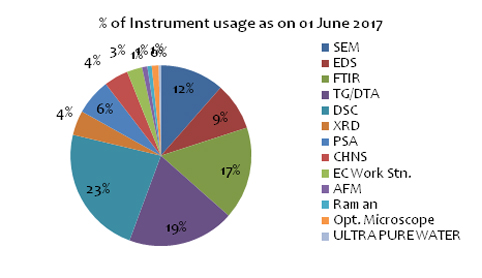

The focus of CoExAMMPC is to promote collaborative, interdisciplinary research and education in the science and technology of materials that will address the future needs of society. Also, promotes collaboration among VU faculty and between VU faculty and researchers of other universities, industry, and government laboratories. The Centre is equipped with necessary state-of-the-art equipment such as SEM/EDS, AFM, XRD, DLS, FT-IR, Raman, DSC, TGA, and many other materials related processing facilities.

Preamble of the centre

Materials Science is an emerging and challenging field to study and acquire the knowledge of materials which are composite to be understood. Progress in the field of materials science and technology has given birth to these fascinating and wonderful materials. Materials science has provoked and contributed to the emergence of various nanomaterials, biomaterials, electronic, optical, magnetic materials, piezoelectric materials, ceramics, glasses, polymers, metal alloys, smart materials, semiconductor materials and design of complicated structures through the innovation of technology by the advancements in the study of materials science.

Significant research and development have been expanded in Composite materials in the recent past. Composites are one of the most advanced and adaptable engineering materials known to mankind. Composites are heterogeneous in nature, created by the assembly of two or more components with fillers or reinforcing fibres and a compactable matrix. It gives the composites their shape, surface appearance, environmental tolerance and overall durability while the fibrous reinforcement carries most of the structural loads thus giving macroscopic stiffness and strength. Reinforced composites serve as an inexpensive, renewable and non-toxic alternative to metals and ceramics. The matrix may be metallic, ceramic or polymeric in origin. A composite material can provide superior and unique mechanical and physical properties because it combines the most desirable properties of its constituents while suppressing their least desirable properties. At present composite materials play a key role in theaerospace industry, automobile industry and other engineering applications as they exhibit outstanding strength to weight and modulus to weight ratio. High-performance rigid composites made from glass, graphite, Kevlar, boron or silicon carbide fibres in polymeric matrices are being studied extensively because of their application in aerospace and space vehicle technology.

Objectives

1. To create the state of art facilities for interdisciplinary research in Universities/Institutions promoting professional activities.

2. To involve all UG / PG/ PhD research scholars from all the departments promoting interdisciplinary and multidisciplinary research mainly encourages research in emerging area of Science & Technology.

3. To do industry sponsored projects.

4. To assist in characterization and to provide analytical characterization, material testing and consultancy services to government and industry.

5. To develop industry-ready, world class engineering graduates.

6. To disseminate research and new technologies for the benefit.

7. To assist in advanced research projects and establish strategic partnerships between the Centre's researchers and industry at national and international levels.

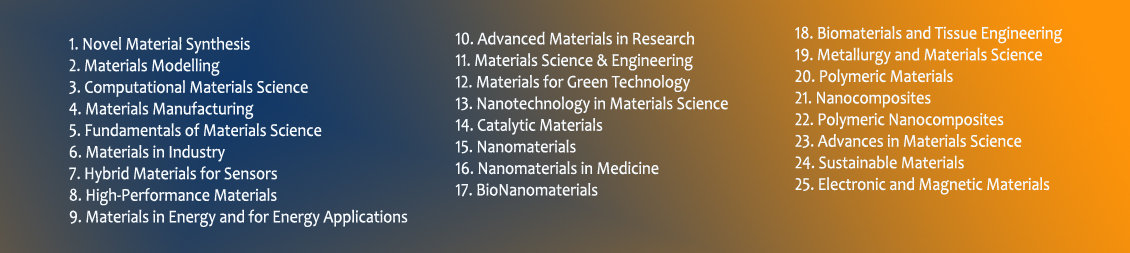

research themes

The Centre of Excellence for Advanced Materials, Manufacturing, Processing and Characterization (CoExAMMPC), started in VFSTR University, Guntur as a major research centre to synthesise, develop advanced materials, manufacture devices and their characterization with a basic set of objective offering high-quality assistance in research.

Some of the research themes include,